Premier’s temporary fence rentals make it easy to create structure and maintain safety at events, construction zones, or other active sites. Our fencing solutions help define boundaries, direct foot or vehicle traffic, and reduce the risk of accidents or unauthorized access. By separating key areas and minimizing confusion, we help you stay in control of your site. It’s a practical and reliable way to manage space and solve the common issues that arise when clear borders aren’t in place.

Common settings where fences are essential:

Portable fencing is a fast, practical way to bring order and safety to your site. At Premier, we deliver and install durable panels suited to your layout, then remove them when your project wraps up. With options for construction zones or event spaces, we tailor each setup to fit your needs.

Our fencing solutions offer the following benefits:

Request A Free Quote

Need site services? Fill out the form below or call us at +1 (604) 210-7451, and we will get back to you as soon as possible!

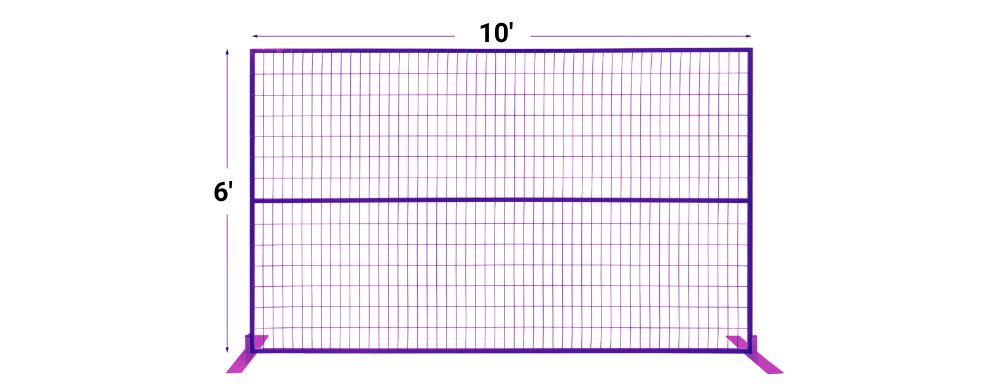

Find The Right Size

For Your Project

Choose from a range of temporary fence panel sizes to suit your site. Ideal for managing access, improving safety, and securing any work area.

It offers sturdy, extended coverage. Ideal for securing large areas, construction zones, or creating temporary barriers.

Commonly Asked

Questions & Answers

Find helpful answers about our services, scheduling, equipment options, service areas, and customer support to keep your project running smoothly from start to finish.

We deliver our site services within 24 hours, however, if you want to reserve a date or book in advance you can contact us to save a slot.

Yes. We have a wide range of fences that can cater to both constructions sites and family-friendly events. Once you contact our team, they will find a suitable temporary fence rental for your event that is made of the right material and ensures the safety of your guests and/or workers.

We are legally the only one allowed to set up of our own fences. This is for legal reasons.

We can provide fence rentals from anywhere between a couple of hours to several years, however, once you have booked a fence rental for a certain amount of time we expect it to be returned accordingly.

Yes, our team will show up for the pickup of the rented equipment once the slot is up or the client calls up for a pick up.

How Does Our Fence Rentals Work?

Our simple process makes site setup easy. From requesting a quote to final pickup, we deliver bins, toilets, and fencing on time with reliable service every step of the way.

Get in touch with us online or by phone to discuss your project needs. We offer fast, free, no-obligation quotes with pricing and recommendations tailored to your site.

We’ll assess your site to confirm the right equipment, placement, and service plan. Once everything’s set, we schedule the job to keep your project moving.

We deliver on your schedule to ensure your project stays on track. Same day options are often available for bins. We’ll do our best to get you the next available delivery!

Once you're done, we’ll take care of the rest. Our team returns for timely pickup, leaving your site clean, clear, and ready for what’s next with no extra effort required.

Trusted By People Like You

We’re proud to have supported a wide range of clients across industries with reliable site services tailored to their unique project needs and timelines.

Serving construction, events, film sets & more

What People Say About Us

See what our customers are saying about their experience with Premier Site Services and why they trust us for reliable, stress-free site solutions across BC.

Known for reliable service and strong community trust, we deliver expert site solutions across the Lower Mainland with a focus on quality, value, and environmentally responsible practices.

Stay Up To Date

Get tips and advice from Premier Site Services. Our blog helps you maintain, protect, and manage your property or project with confidence in any setting.

Premier Site Services / All Rights Reserved.

Website Designed and Developed by Coding Bull.